Features:

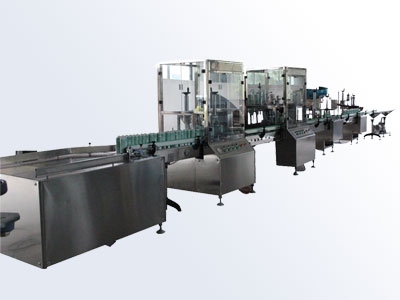

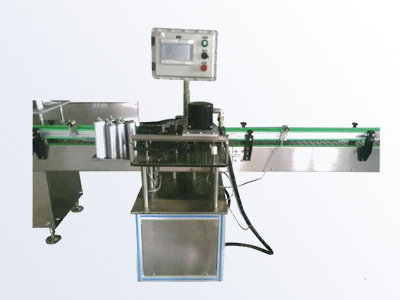

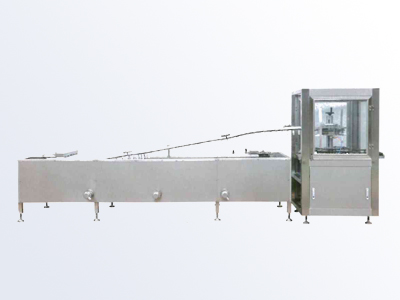

1. The machine is composed of a bottle unscramble table, a white material filling machine, a black material filling machine, a valve machine, a sealing DME inflator, an LPG inflator, an automatic tube-type large cap machine, and an automatic gun-type screw cap machine , Inkjet printer, packaging workbench, finished product swing machine and other equipment.

2. The filling line absorbs foreign advanced technology, the filling head is individually controlled, and no cans are discharged; the sealing head adopts oriented sealing, and the sealing quality is high; the filling head adopts oriented inflation, which is accurate, efficient, and consumes little gas.

3. Batch operation, high production efficiency and stable equipment performance.

4. The equipment has a high degree of automation, and all procedures are completed by machines, saving labor costs.

5. All air control valves adopt national standard air control valves, and all open design, easy to replace and easy to buy.

6. The production line equipment has been practiced on the production site for many years, and after continuous detail improvement, its safety and practicality have been praised in the industry.

Product application range:

This machine is a special equipment for polyurethane foam sealant to meet the needs of mass production enterprises. It is an ideal equipment for various door and window factories, rubber factories, real estate and other related industries.

TEL

TEL